Saving Fuel by Trim Optimisation

Date: September 21, 2021

Vessel Type: 36000 DWT Bulk carrier

Scope of Assessment: To find out the Power & Fuel saving of the bulk carrier vessel by following the optimum trim condition and validate the CFD method of optimum trim.

Result:

The vessel operated under the optimum trim condition for 4 months. The vessel had 5.9% fuel savings. This translates to a significant annual savings of 323 tonnes of fuel and 162K US$.

Background: Effect of trim

Ship trim optimization simply advocates selecting the trim condition for minimum resistance at the given draft (displacement) and speed. The resistance through water decides the

power and the fuel consumed. Hence, less resistance implies lesser emission and more economical operation by fuel savings. The power required varies with trim, draft, and speed of a ship. Determining the most efficient trim from analyzing all these combinations through experimentation is impractical whereas thorough computational fluid dynamics (CFD) simulation, can easily be obtained. Ship management can further focus on creating awareness in the crew about the economic and ecological value of the fuel savings and emission reduction, through operation at optimum trim. The information can then be used to adjust the trim of the vessel. If extra ballast is required to re-trim the vessel, this can be considered to find the new optimum trim including the ballast weight.

Optimum trim:

Various trim cases were considered for finding the condition in which power consumption could be minimized. This study was carried out for numerous cases by varying speed and draft ranges. A significant decrease of the ship resistance for the analysed models was achieved and validated by the comparison with the well-known sea-trial and model test result database. After considering all factors, where the power consumption is minimal is termed as the optimum trim. Power trim table for scantling and ballast draft at various draft shown above the red marked point shows the lowest power corresponding to the various speed

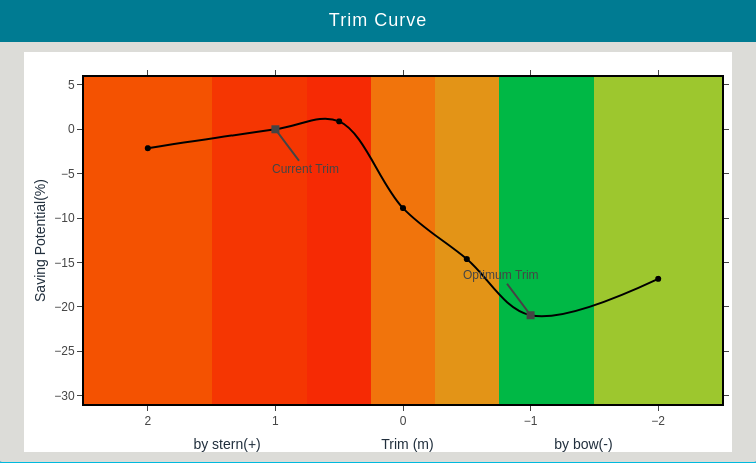

Savings Potential:

Optimum trim for the vessel may be different from the current operation trim of the vessel. Vessels can attain the optimum trim in two ways – by keeping the same displacement without extra ballast or by adding ballast. In the former case, there is a fuel-saving which the ship can achieve by just re-arranging the ballast or cargo. In the latter case, a different saving is achieved by adding extra ballast. In any case, it is evident that the ship can attain some fuel savings by changing the trim compared to the current operating conditions which is called saving potential. Each trim different from the current operating trim has some saving potential which may not be optimum but maybe the best achievable trim. The saving potential is calculated considering the improvement that can be made from the current operating trim.

Methodology:

Optimum trim of the subject vessel is 1 m by aft for laden conditions. The ideal way to find the fuel savings is to compare the fuel consumption of the vessel during the period of optimum trim and non-optimum trim. To avoid the effect of displacement in fuel consumption, we have taken a constant displacement for comparison. So comparing the fuel consumption between both the voyages, we can see the savings for keeping the optimum trim. The vessel has reported wrong power values for some period, hence brake power, converted from the fuel using the SFOC curve is considered for the analysis. Since we are interested in the change in power requirement, brake power can also be used for the analysis. The brake power is corrected for weather using ISO 19030 standards. Since the analysis is done for a shorter period (four months), the degradation effect is unlikely to affect the results.

Conclusion:

Trials on the bulk carrier vessel reveal a potential savings of 323 tons (5.9%) of fuel and 162K US$ annually. Trim Optimization offers a simple but effective way to save fuel and money.