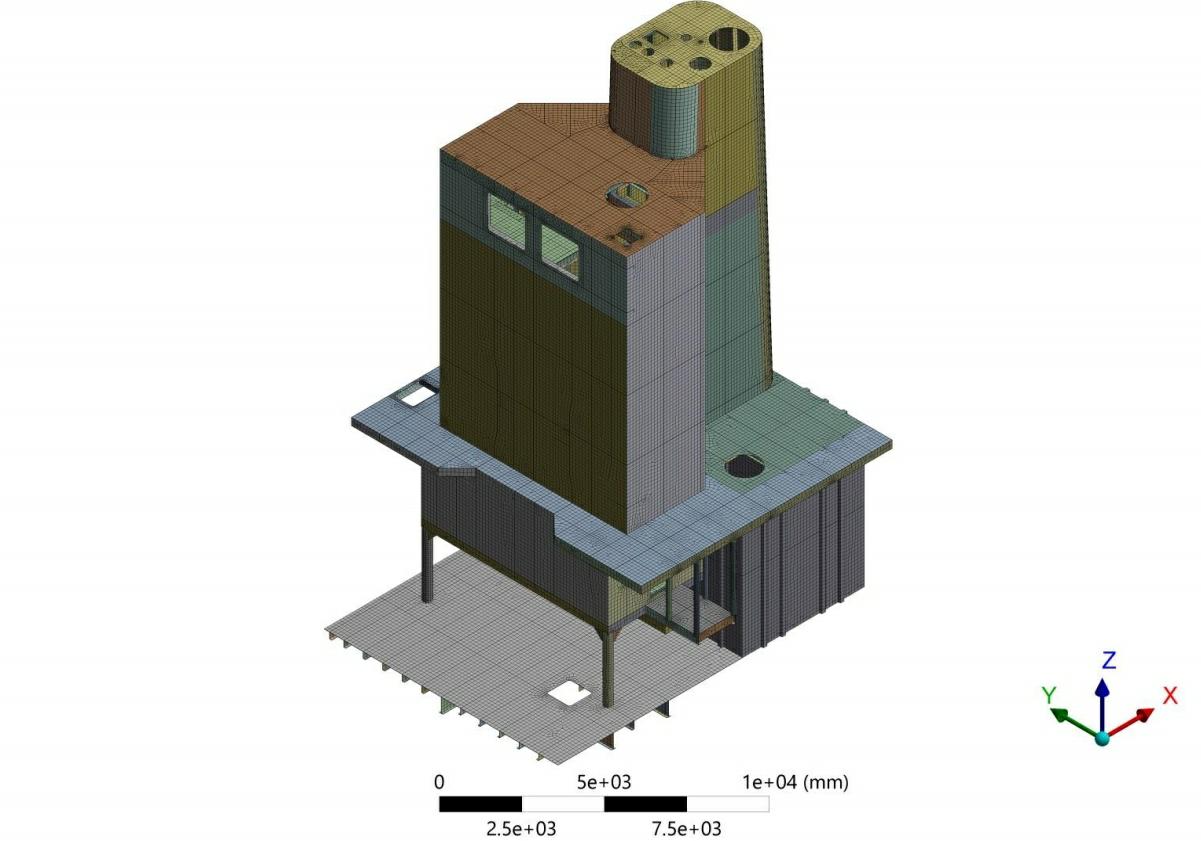

Design of Scrubber Casing

Date: January 20, 2021

Vessel: 82,938 MT Bulk Carrier

Background: In order to comply with IMO 2020 Sulphur cap, the vessel owners intended to install a scrubber on-board the vessel to wash off the Sulphur components from the exhaust. Since there is not enough space to install the scrubber inside the engine room or the funnel, it was decided to install the scrubber inside a separate casing (backpack) at the aft end of the vessel.

Scope of Assessment: Engineering study and design of the scrubber casing as per relevant Classification Society requirements.

References:

- IACS Common Structural Rules for Oil Tankers and Bulk Carriers

- Class NK Rules for the Survey and Construction of Steel Ships

Design Tools:

- Solidworks

- Autocad 3D

Methodology:

Element Type : 100mm x 100mm 4-noded shell elements

Material of Construction: NK Grade ‘A’ (Min. Yield Strength = 235 MPa)

Contingency Factor: 30%

Maximum Allowable Von Mises Stress: 188.00 MPa

Maximum Induced Von Mises Stress: 169.61 MPa

Result:

- Optimized Scantlings

- Ease of Construction

- Hassle-free pipe routing inside the casing

- Enough Maintenance Space

- Access to all deck levels and all around

- Suited for Modular Construction