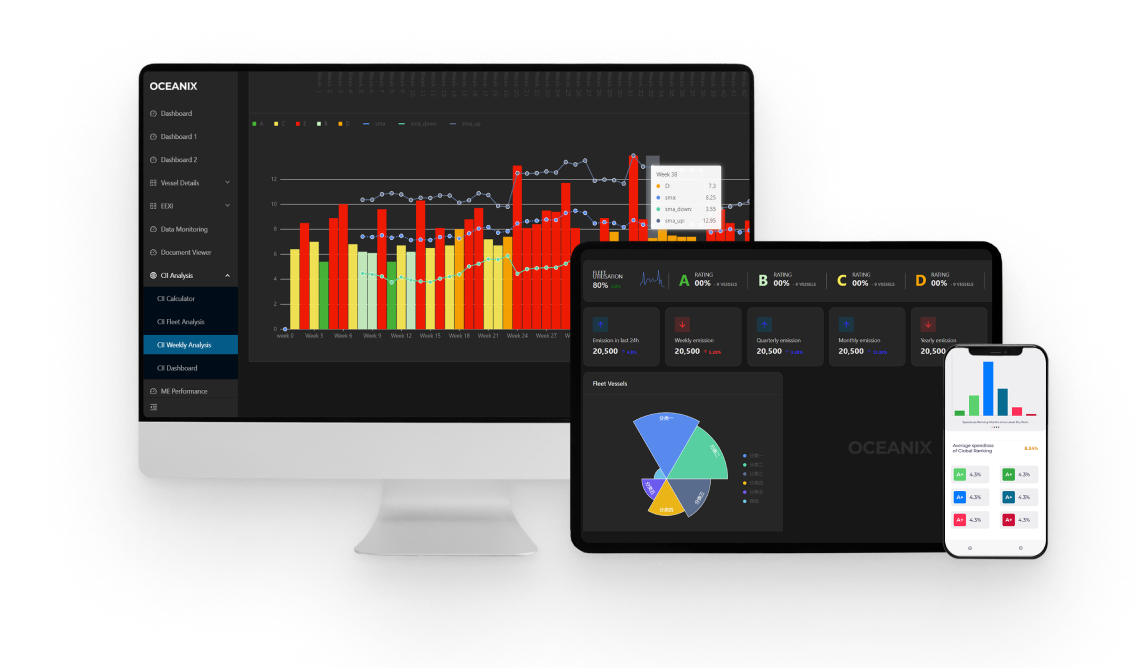

Oceanix provides data science solutions that focus on ship design, vessel performance analytics, mobile applications and vessel data management. We analyse ship data and help shipowners with viable solutions to save fuel, thereby reducing operating expenses. Our ship design services offer efficiency to vessels, thus helping vessel managers and owners to save fuel, money, and time.

Oceanix provides data science solutions that focus on ship design, vessel performance analytics, mobile applications and vessel data management. We analyse ship data and help shipowners with viable solutions to save fuel, thereby reducing operating expenses. Our ship design services offer efficiency to vessels, thus helping vessel managers and owners to save fuel, money, and time.

Oceanix is dedicated to optimizing fuel efficiency, driving decarbonization, and delivering top- tier service quality. Through our advanced cloud-based platform, we actively support ship owners, vessel operators, and fleet managers across every aspect of vessel performance, ensuring the highest standards are met.

Oceanix is a leading provider of data science solutions with a strong focus on optimizing various facets of maritime operations. From ship design and vessel performance analytics to mobile applications and vessel data management, Oceanix computes and delivers the insights every shipping company needs to maximize their fleet performance and savings.

Through X Marine, the panoply of all our products, and services, Oceanix empowers fleet managers and vessel operators to enhance efficiency, ultimately leading to substantial savings in fuel, time, and money. Additionally, the cloud-based platform assists in tracking vessel performance, assessing effectiveness of various maritime activities like drydock and facilitates easy data handling and management.

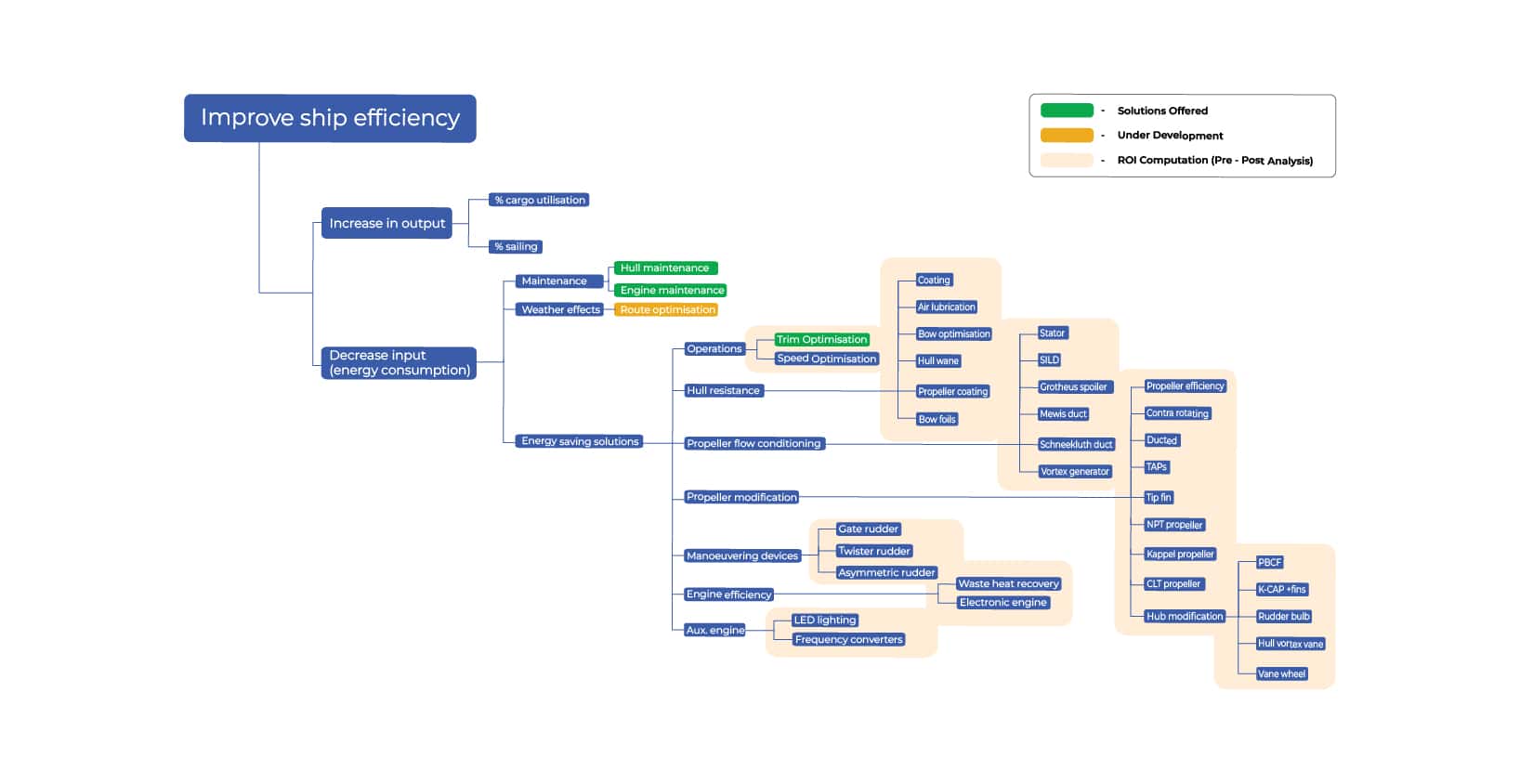

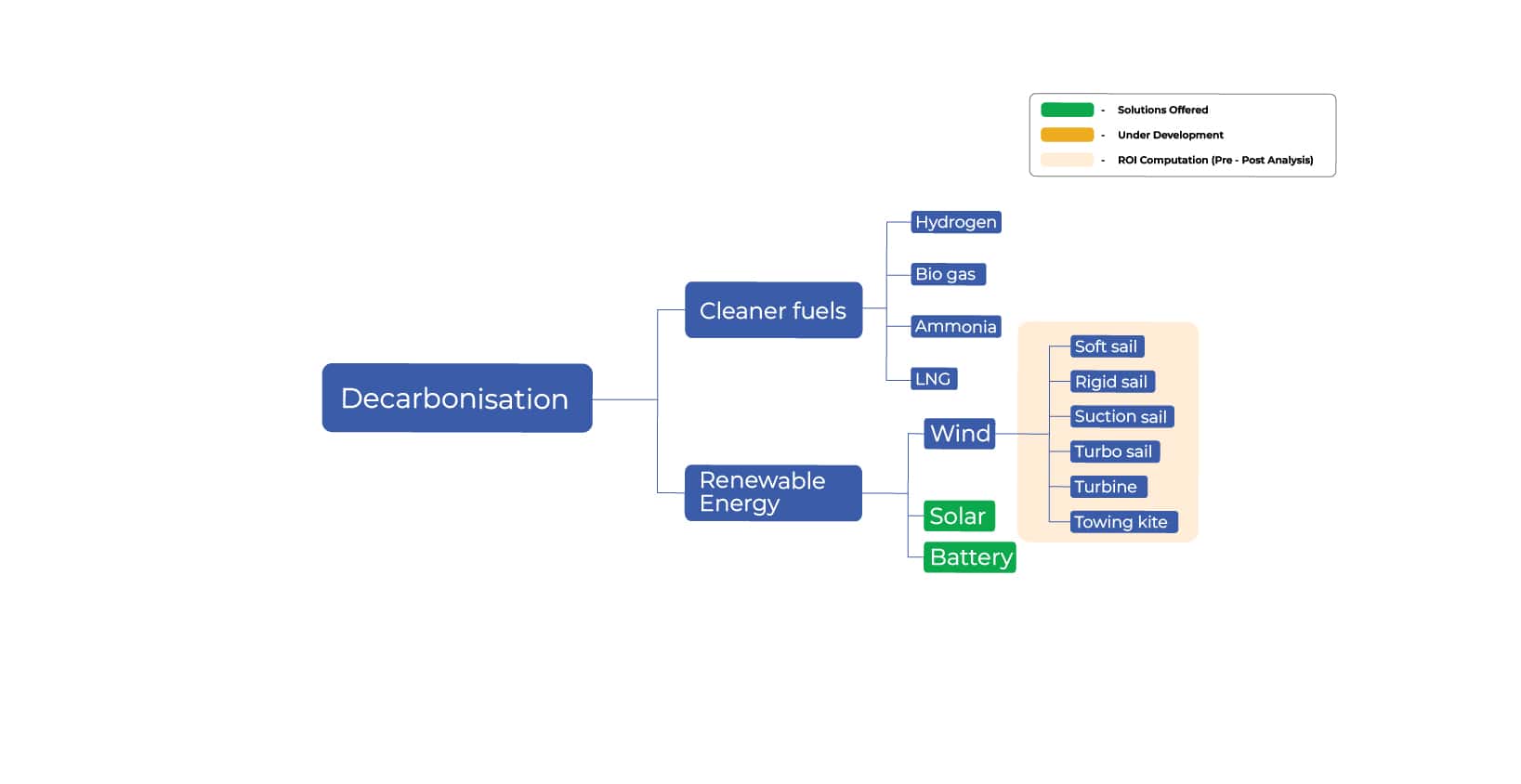

The journey towards decarbonization begins by understanding where you stand. The Global Vessel Ranking System empowers both vessel owners and operators to identify key areas to enhance vessel performance, reduce operational costs, and comply with environmental regulations.

Get your vessels ranked based on the industry’s hottest Indicators like CII, EEOI, Speed Loss, SFOC Deviation and Cargo Utilization, for discovering insights for target improvement areas and performance optimizing pathways.

X-Fleet

X-Data

X-Hull

X-Trim

X-Zero

X-Mach

8 The Green, Dover,

Kent, Delaware, DE 19901, USA

Email: sales@oceanix.cloud

© Copyright 2023. All Rights Reserved, Oceanix